features

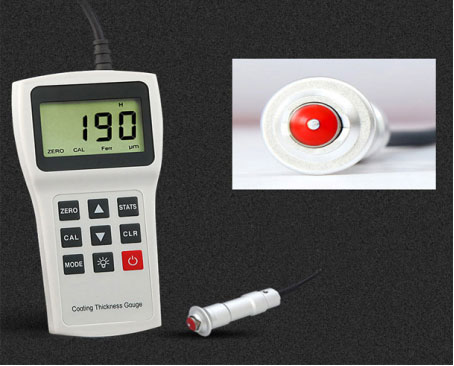

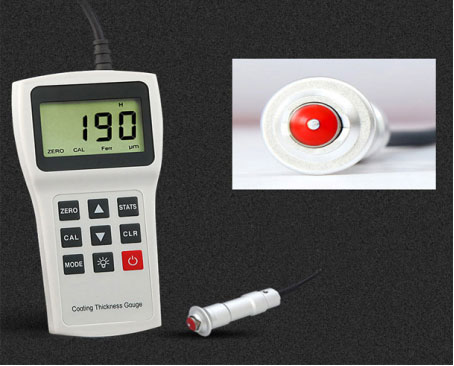

Purchase paint depth gauges online with zero point, one point, two point three calibration. The high-performance appearance consists of easy-to-use large buttons and dynamic measurement probes for measuring surfaces. The digital coating thickness gauge can automatically identify non-ferrous and ferrous metal substrates. Suitable for aluminum, steel, and iron.

Easy to use

1. Large button, easy to operate.

2. High contrast LCD screen.

3. Durable probes.

accuracy

High 1. Good repeatability.

2. High measurement accuracy.

3. Soft probe needle and thread, not easy to break.

application

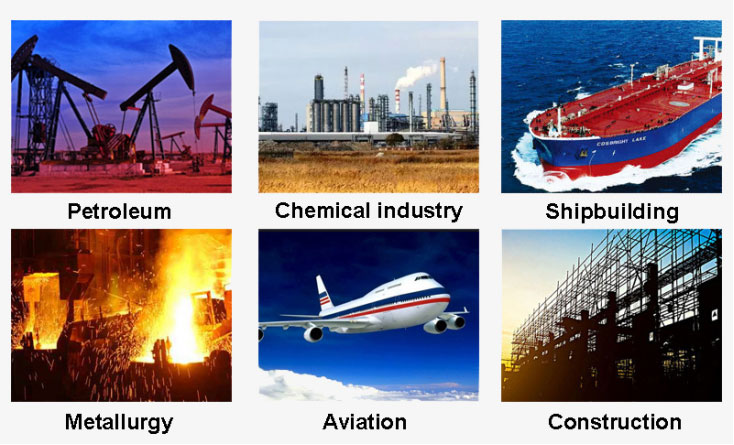

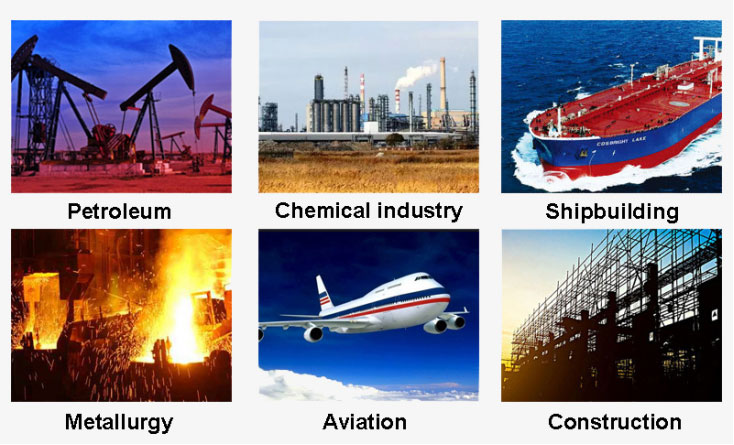

The measurement of coating thickness is an important quality inspection process in the metal processing industry. The coating thickness gauge perfectly handles these situations, greatly improving manufacturing efficiency, and is therefore widely used in metal processing, chemical engineering, commercial testing, electroplating, spraying, aluminum profiles, steel structures, etc. It is also applicable to industries such as shipbuilding, aerospace, power, boiler inspection, and technical supervision.

FAQ Q1: Is the laser rangefinder accurate?

A1: The laser measurement accuracy is within 1/8 inch, measuring up to 50 feet. It makes this measuring tool more accurate, simpler, and faster than a tape measure.

Q2: How to choose a laser rangefinder?

A2: Most laser measuring instruments are easy to place in the palm of the hand, but some laser measuring instruments are larger than others. If your hands are small and you want a small device that is easy to control, or if your hands are large and you need a larger laser for ease of use, please check the exact size of any model you are considering.

Q3: Does the laser rangefinder work outside?

A3: If you are working outdoors, an optical sight or digital point finder is necessary. Without a sight or point finder, you can see a laser spot at a distance of about 30 feet on bright days. It is very likely that if you measure outside, 30 feet will not be reduced.

Reminder: How to maintain the digital coating thickness gauge?

Coating thickness gauge is a widely used control tool among coating and testing personnel. With a little maintenance and upkeep, these mechanical and electronic instruments can provide years of high-quality service.

1. Do not wait for calibration

Before and occasionally after use, it is advisable to read the user manual again to familiarize oneself with the characteristics and functions of the instrument. Record the model, serial number, and purchase date in the user manual, and highlight maintenance and calibration prompts.

2. Use it, but do not overuse it

Now that you have completed the writing work, please measure on the test panel or gasket provided with the measuring instrument. You can also use parts of office furniture or other metal painted objects to ensure that the measuring device is working properly and that you are using it correctly. Measuring instruments come in different shapes and sizes. Make sure you know the correct way to grip and use the model. Most handheld scanners measure once at a time. Lift the probe at least 5 centimeters off the surface between two measurements. Moving the probe on the surface will shorten its lifespan.

3. Put away

Before putting it away, please check the probe first. It can remove fresh paint or other materials, directly solve the problem, and avoid unpleasant accidents during the next use. For users, not using batteries and probes in a short period of time is usually not a problem. Put the measuring instrument back into its original bag or packaging. Cover the probe. Store the instrument in a dry place, away from magnetic flux and extreme temperatures. When you are looking for a new use, you need to quickly check the known thickness. This does not include the need for regular and scheduled maintenance. Don't forget to place the user manual and spare battery next to the instrument panel. Whether it is magnetic or eddy current measurement methods, coating thickness gauges only require a little regular attention to ensure accurate and reliable service for many years.

Technical indicators

型 | 是-CM10FN | 是-CM10N | 是-CM10F | 是-CM10FH |

测量范围 | 0-1500微米 | 0-2000微米 | 0-3000微米 | 0-10000微米 |

精度 (μm) | ± (2%H+2) μm | ± (2%H+2) μm | ± (2%H+2) μm | ± (2%H+10) μm |

工作原理 | 磁感应/涡流 | 涡流 | 磁感应 | 磁感应 |

小曲率半径 | 5毫米 | 5毫米 | 5毫米 | 10毫米 |

基板的 小直径 | 20毫米 | 20毫米 | 20毫米 | 40毫米 |

基板的 小厚度 | 0.5毫米 | 0.5毫米 | 0.5毫米 | 2毫米 |

显示 | LED显示屏 |

工作温度 | -10-50°摄氏度 |

统计学 | 测量次数、 大值、 小值、平均值、标准差 |

校准 | 零点、一点、两点校准 |

电源 | 2*1.5V AAA电池 |

尺寸 | 149 * 73 *32毫米 |

净重 | 0.2千克 |

自动关机 | √ |

External dimensions

CN

CN