features

Small portable gas flowmeter with digital display, flow range of 0-20L/min, high sensitivity, good repeatability, can accurately track flow, widely used in industries such as electromechanical, food, chemical, pharmaceutical, etc.

No need

Temperature compensation 1. The sensing chip adopts thermal mass flow measurement to ensure high-precision measurement of the flowmeter.

2. The digital gas flowmeter has high stability, high accuracy, and excellent repeatability across the entire range.

Flexible output

1. Actively upload data through communication interface.

2. The digital gas flowmeter allows for on-site configuration of flowmeter parameters using a keyboard.

application

Gas Flowmeters are widely used in fields such as petrochemicals, natural gas industry, environmental protection, energy metering, modern agriculture, water conservancy construction, biotechnology, pipeline transportation, aerospace, scientific experiments, etc.

common problem

Q1: Can the digital gas flowmeter have perfect accuracy?

A1: In an ideal situation, the flow reading of the process instrument will be completely correct without any type of deviation. Unfortunately, this is not the case, and inherent errors in measurements must always be identified, considered, and minimized as much as possible.

Q2: Does the digital gas flowmeter need to be calibrated?

A2: In the production process of Flowmeters, several steps are required, such as coil winding, lining processing, and electrode assembly. This series of operations will cause a certain degree of error and dispersion in the equipment, so a calibration process is needed to correct the accuracy.

Q3: Does the digital gas flowmeter have temperature compensation function?

A3: Yes. As long as these temperature changes are within the temperature compensation range, the output reading will compensate for the temperature changes.

Tip: What factors can affect the measurement accuracy of an electromagnetic flowmeter?

1. The liquid to be tested contains bubbles.

2. The liquid to be tested is not full in the pipeline.

3. Short circuit effect of conductive deposits.

4. Crystallization occurs in liquids.

5. The conductivity of the liquid exceeds the allowable range.

6. Space electromagnetic interference.

7. Asymmetric flow rate of the fluid to be tested.

8. The vibration at the installation site affects the accuracy of the Flowmeter.

Technical indicators

type | It's -MF5706 | It's -MF5708 | It's -MF5712 |

Flow range | 0~20L/minute | 0~100 L/min | 0~250 L/min |

Power Supply | 4 AA batteries (LR6) or 5-24V DC |

The power adapter | Input: 100-240V AC, 50/60Hz, Output: 7V DC, 0.2A |

power waste | ≤10mW |

signal output * | RS 485 Interface |

display | Liquid crystal display |

Display unit | Instantaneous flow rate: L/min, accumulated flow rate: m ³ |

Instantaneous flow resolution | 0.01 L/minute |

Cumulative resolution of traffic | 0.001 m³ |

working pressure | ≤0.8MPa |

pressure loss | ≤600Pa | ≤1000Pa | ≤2000 years Pa |

working temperature | -10°C ~ +55°C |

keyboard | 3 keys |

user interface | Type-C USB (This interface is connected to a power adapter for power supply, with a power cord of 0.5m, and can also be used as a connection interface for 485 communication.). |

calibration | air @20°C, 101.325kPa |

Public Security | 6mm | 8mm | 12mm |

Mechanical connection | NPT 1/4” | NPT 3/8” | NPT 1/2” |

weight | 185g(Copper body) | 270g(Aluminum alloy body) | 350g(Aluminum alloy body) |

Protection level | IP40 protection level |

gas* | 1. Power adapter with 0.5m cable

Type-C USB 2.RS485 data cable, Type-C USB port |

accessories | IP40 protection level |

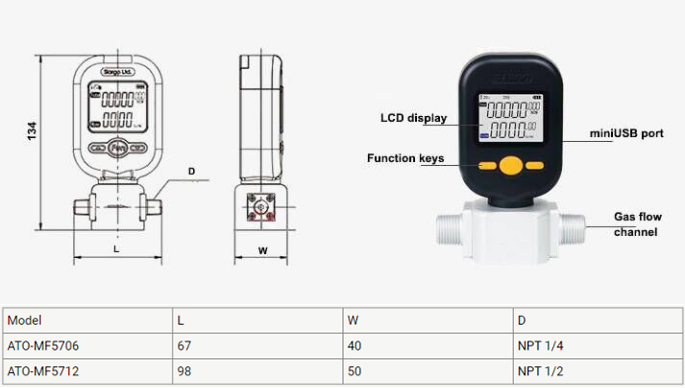

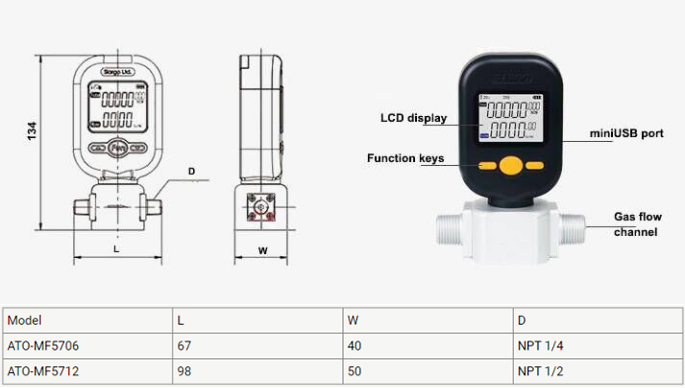

External dimensions

CN

CN