features

The electromagnetic flowmeter has stable and reliable performance, sensitive response, strong anti-interference ability, output signal of 4-20mA, and nominal diameter of DN15~DN200 to choose from. The electromagnetic flowmeter has strong adaptability and is compatible with various pipelines, suitable for all conductive liquids such as domestic water, industrial water, sewage, etc.

Newly upgraded protective needle

1. Fully protect the instrument head, reduce interference, and ensure more accurate signal transmission.

2. Magnetic Flowmeter displays instantaneous cumulative flow rate.

The electromagnetic flowmeter uses pure copper coils

1. Pure copper coils ensure stable and accurate signal output.

2. Improve the reliability of the instrument.

application

Magnetic Flowmeters are used for measuring and controlling industrial and agricultural flow in industries such as petrochemicals, steel metallurgy, water supply and drainage, irrigation, water treatment, sewage treatment plants (environmental sewage control, chemical sewage, electroplating sewage), papermaking (pulp), mud, medicine, food, etc.

Common question Q1: Can the electromagnetic flowmeter have perfect accuracy?

A1: In an ideal situation, the flow reading of the process instrument will be completely correct without any type of deviation. Unfortunately, this is not the case, and inherent errors in measurements must always be identified, considered, and minimized as much as possible.

Q2: Does the electromagnetic flowmeter need calibration?

A2: In the production process of Flowmeters, several steps are required, such as coil winding, lining processing, and electrode assembly. This series of operations will cause a certain degree of error and dispersion in the equipment, so a calibration process is needed to correct the accuracy.

Q3: How often does an electromagnetic flowmeter need to be calibrated?

A3: Magnetic recalibration of Flowmeter every two years (every two years) or at the manufacturer's specified low frequency. The readings of the small frequency meter specified by the manufacturer are pressure corrected and moisture content corrected if necessary.

Kind reminder: What is an electromagnetic flowmeter?

A magnetic flowmeter or electromagnetic flowmeter is an instrument based on the principle of electromagnetic induction, which measures the flow rate of a conductive fluid by generating an electric potential through an external magnetic field. The structure of an electromagnetic flowmeter mainly consists of a magnetic circuit system, measuring tube, electrode, housing, lining, converter, etc.

Technical indicators

type | It's-LDG |

secondary | Conductivity liquid (≥5uS/cm) |

Nominal diameter * | DN15~DN200 |

Nominal pressure | 1.6MPa |

Speed range | 0~10米/s |

accuracy | ±0.5%R |

to configure | Integrated or remote |

High medium temperature | Integrated style | +80°centigrade |

Remote type | +80°C (CR) or +120°C (F4) |

Range ratio | Integrated style | 20:1 |

Remote type | 10:1 |

ambient temperature | sensor | -25°C~+180°C |

Transformer | -10°C~+60°C |

Pad material * | Chloroprene rubber (CR) or polytetrafluoroethylene (F4)(

Customized materials: polyurethane rubber PU, F46) |

Electrode material * | Stainless steel 316L

(Customized electrodes: Hastelloy C, Hastelloy B, titanium, tantalum, platinum) |

Electrode form | Interpolation |

Number of electrodes | Standard configuration includes 3-4 electrodes (two measuring electrodes and one grounding electrode) |

output signal | 4-20 MA |

Cable entrance size | M20 × 1.5(Nylon waterproof connector) |

supply voltage* | 110V/220V AC power, 50Hz/60Hz; 24V DC ± 10% |

power waste | ≤15VA |

signal communication | RS-485,Support standard Modbus RTU protocol |

Flange standard | Complies with the international GB9119 standard |

Flange material | carbon steel |

Grounding ring material | stainless steel |

Shell material | carbon steel |

Protection level | IP65 Protection level |

Cable length (remote type) | 10mConnection line (standard) |

Attention: * Please note that all options may not be listed in the selection area, including nominal diameter, lining material, electrode material, etc. If you have any requirements, please contact us.

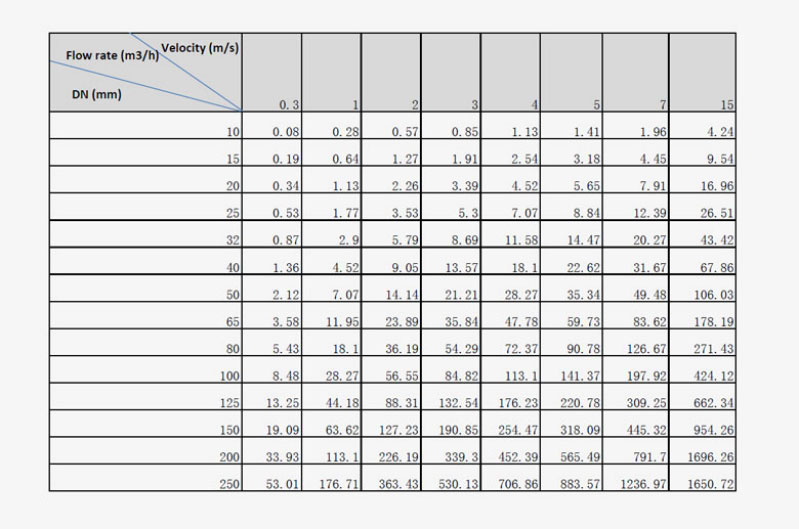

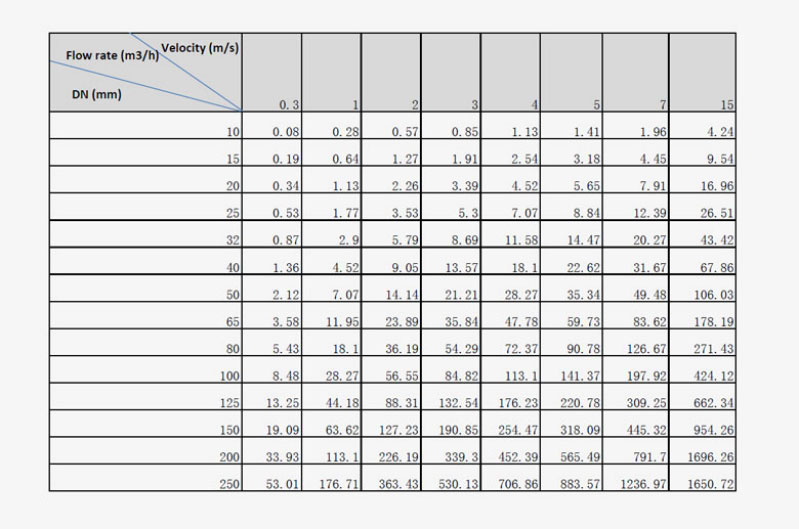

Magnetic flowmeter flow rate

CN

CN