features

The popular pressure gauge offers a measurement range of 0-11 bar, a 40mm dial diameter, a dual scale display screen, stainless steel material, and 1/8 "BSPT thread. The 0 to 160 psi pressure gauge is designed to measure water pressure, hydraulic pressure, oil pressure, and air pressure, and is suitable for metallurgy, power, petroleum, chemical, light industry, and machinery.

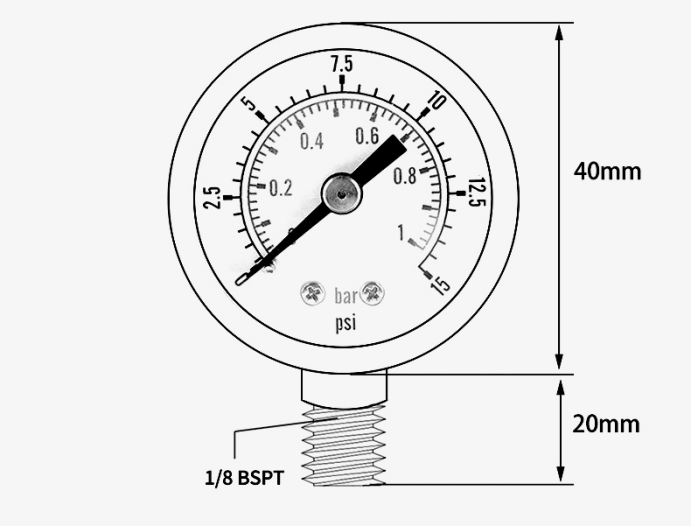

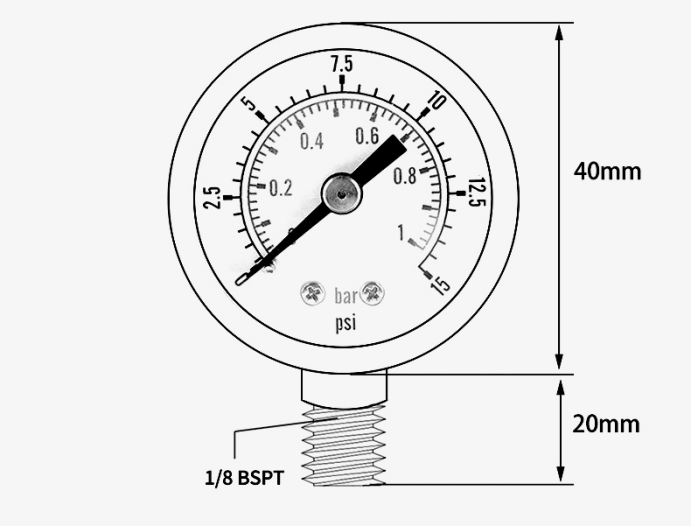

Pressure gauge, with a diameter of 40mm dial, 1/8 installation diameter, BSPT thread, measuring range of 0~160psi&0~11bar.

1. 0-160psi pressure gauges can be used as water pressure gauges, air pressure gauges, hydraulic gauges, and oil pressure gauges.

2. The circular dial adopts a stainless steel shell, which is corrosion-resistant. The diaphragm pressure gauge provides clear readings and is weather resistant.

3. Brass and stainless steel fittings for measuring the pressure of non corrosive liquids and gases. Such as pressure testing for water, oil, fuel, coolant, air, CO2, nitrogen, argon, etc.

4. Dual scale pressure gauge (0~160psi/0~11bar). The display accuracy is 2.5% across the entire instrument range.

5. It also features a lower mounted male connector with 1/8 "BSPT thread.

application

A pressure gauge is a commonly used measuring instrument for displaying and controlling pressure. Diaphragm pressure gauges are widely used in industries such as chemical, petroleum, metallurgy, mining, and power production, especially in automotive repair workshops, heat pipe networks, water and gas supply systems, etc.

common problem

Q1: What is a pressure gauge?

A1: A pressure gauge refers to an instrument that uses elastic elements as sensitive components to measure and indicate pressures higher than the environment. It is used in almost all industrial processes and research fields, mainly for thermal pipelines, oil and gas transportation, water and gas supply systems, and vehicle maintenance. Mechanical pressure gauges, especially in industrial process control and technical measurement processes, are becoming increasingly popular due to their high mechanical strength and easy production of elastic sensitive components in maintenance workshops.

Q2: How does a pressure gauge work?

A2: The pressure gauge transmits pressure deformation to the pointer through the elastic deformation of sensitive components inside the watch (Bourdon tube, diaphragm box, bellows), and then rotates the pointer through the conversion mechanism of the watch movement to display pressure. This is the working principle of a pressure gauge.

Q3: What is a pressure gauge used for?

A3: Pressure gauges are both pressure gauges and water pressure gauges, mainly used for pressure detection in industries such as metallurgy, power, petroleum, chemical, light industry, and machinery. The pressure gauge relies on measures such as internal filling of damping oil and supporting buffering devices, which have good impact resistance. Suitable for situations where the pressure of the measured medium undergoes strong pulse changes or pressure shocks, and is often suddenly released during production, as well as environmental vibrations. Pressure gauges can measure the average pulsating pressure of gases and liquids, thereby overcoming the damage caused by strong pulses of the medium and environmental vibrations, and ensuring the accuracy of readings.

reminder:

Pressure gauge

Three issues in use: 1. The fan gear of the pressure gauge will wear out after working for a period of time.

The pressure measurement system of the pressure gauge is affected by the instantaneous overpressure of the measured medium, which prevents the pointer from returning to zero or rushing to the limit pin.

After the system is depressurized, the pressure gauge pointer will not return to zero.

The issue with the pressure gauge

3 solutions: 1. Increase the width of the contact surface of the sector gear to achieve wear resistance and increase the service life of the pressure gauge.

2. Install limit blocks on the movement of the pressure gauge. When the pressure measurement system is subjected to instantaneous impact, the cylindrical and sector gears of the movement are not easily tripped, thus solving problem 2.

3. Close the valve below the pressure gauge in the impact pressure measurement system.

Technical indicators

Model: YES-TS-Y408-160psi.

Dial diameter: 40mm.

Installation method: radial.

Range: 0~160 psi, 0~11 bar.

Installation diameter: 1/8.

Thread specification: BSPT.

Size: 6x4x2.5cm.

Material: Stainless steel.

Packaging size: 8.5x6.5x4.5cm.

Product weight: 44g.

Packaging weight: 60 grams.

External dimensions

CN

CN